Section under repair

The first permenant winder at the South pit was built by the Worsley Mesnes Iron Co. in 1874. It had a pair of horizontal cylinders, 34in diameter and 6ft stroke, ordinary slide valves and a plain drum 16½ ft by 6ft 10in. The operating pressure was 48 lb/in2

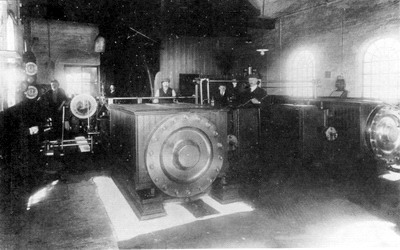

No photograph of this winder have been located but a photo of the main winder at the sister colliery at Teversal shows a similar arrangement to the one which would have been at Pleasley.

Teversal Colliery winder circa 1905

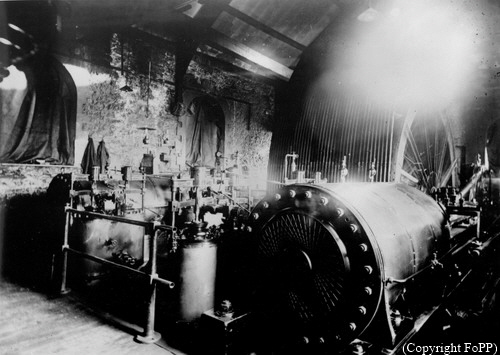

The second winder at the South pit was made by Readers of Nottingham and installed in 1900. This had two horizontal cylinders, 42in diameter and 6ft stroke, fitted with Cornish valves and a drum 21ft by 6½ ft. The boiler pressure was 100 psi and the operating pressure would be about 90 lb/in2.

South-pit Reader winder circa 1904 (copyright FoPP)

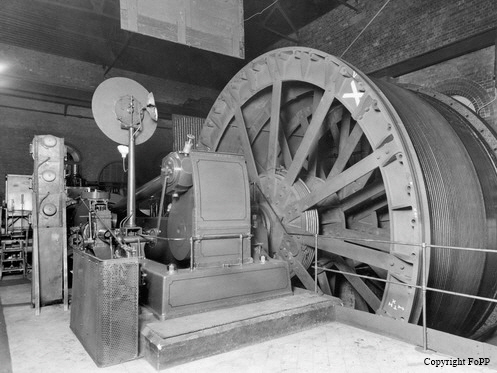

The third and final winder at the South pit was manufactured by Markhams of Chesterfield and installed in 1922. In August 1920 a considerable number of tenders for the new winder had been received, but the ones which were liked the best were from Markhams and Thornwill & Warham, the latter being “substantially stronger in all points” than the former. It was agreed that the “stronger tender” was worth an extra £2000 although exactly what the difference was is unknown.

Endeavours were made to get a firm quote from Thornwill and Warham, but this does not seem to have been forthcoming and after Markhams gave a firm price at the begining of October the contract was awarded to them.

The initial Markham design proposal, drafted on 13th September 1920, was based upon a winder installed in 1913 for the Butterly Coal and Iron Co. at their new colliery at Ollerton. It had two 36in by 84in horizontal cylinders fitted with double-beat drop valves. The 20ft by 11ft 6in timber-lagged drum was serviced by a steam brake-engine operating two pairs of post brakes onto Vee’d brake rims. A Whitmore overwind device was employed.

A number of changes were made to the proposed design, however. It had the same general layout but with the controls now on the right-hand side. The drum was replaced by a 21ft by 10ft one with steel plate lagging, scrolled at the outer coils to overcome problems with the relatively wide fleet angle at Pleasley due to the proximity of the headgear sheaves and the potential depth of wind to the Blackshale seam. A pair of powerful, under-slung Burn’s type brakes, operating onto Vee’d rims were substituted for the smaller post brakes and a Thornwill & Warham ‘profile’ overwind device, driven from the depth indicator shaft was fitted in place of the more out-dated chain driven Whitmore unit.

South-pit Markham winder circa 1950 fitted with a Burn’s type underslung brake and a Thornwill and Warham overwind controller.

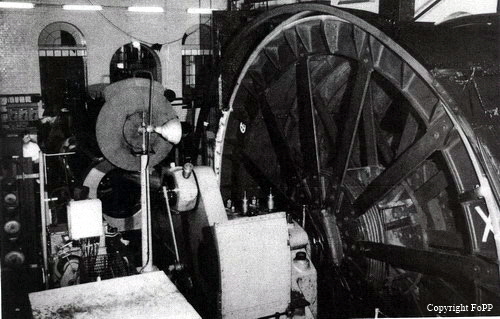

Since its installation in 1922, relatively few changes have been made to the South winder. In the 1950s, the underslung Burn’s brakes were replaced by a pair of suspended post brakes using the same brake engine and the Vee’d rims. In the mid 1960s these brakes were then replaced by the present Robey-Crompton pillar brakes. These used flat brake shoes, and the Vee’d rim segments were replaced by flat profiled ones. They brakes were hydraulically operated and the steam brake engine was dispensed with. The Thornwill and Warham overwind device was also replaced by a Blacks Modified Torque device - probably at the same time since this was able to provide electrical interfaces to the brake operating system.

South-pit Markham winder circa 1975 fitted with Robey pillar brakes and a Blacks Torque controller

Whilst the new Markham winder was being fitted, a temporary winder was installed to the south of the headstocks to maintain the second means of egress and to handle the dirt from the Deep Hard roadway headings. This was a Thornewill & Warham machine originally installed at Gilfach Colliery in South Wales and purchased from the Powell Duffryn Co. in order to replace the previous temporary winder destroyed in an overwind accident shortly after it began operation in January 1921. The Thornwill & Warham winder was subsequently transferred to Bilsthorpe Colliery for the sinking of the upcast shaft and continued in use there until the 1970s when it was replaced by an electric winder.

References

- Colliery Guardian 1951

- Notts. Mining Students Assoc. Jrnl 1923

- Stanton Ironworks Co. Minutes, Derbyshire County Records Office

- Markham & Co. Ltd. engineering drawing # 20142 (1920)

- Markham & Co. Ltd. engineering drawing # 20310 (1921)

- Markham & Co. Ltd. engineering drawing # 20311 (1921)

- Markham & Co. Ltd. engineering drawing # 26562, 26563, 26564 (1950)

- Markham & Co. Ltd. engineering drawing # 577/64/B (1964)

Copyright © 2005 - 2020 J.S. Thatcher

Page updated on:

02 Aug, 2020

at

09:06:47 PM

In case of problems contact: