Section under development

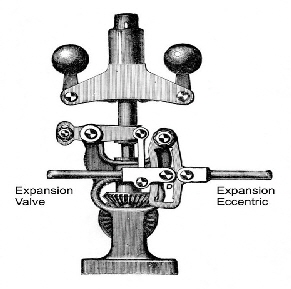

The Hartnell governor was a compact and sensitive device suitable for use on high speed engines. Its original purpose was to maintain a constant engine speed by automatically adjusting the expansion valve timing.

It was later adapted for the special requirements of winding engines

Early Hartnell governor arrangement

Its purpose was to operate a trip mechanism on the steam inlet valves so as to limit the amount of steam entering the cylinder after the winder had reached a certain speed. The initial acceleration to get the winder under way required considerable more power (i.e. steam) than that which was needed for the subsequent steady running. By limiting the amount of steam entering the cylinder and then allowing that which was there to give up its energy by expanding, considerable economy in steam consumption could be achieved once the acceleration had been completed.

Unlike the governors on steam engines where a constant speed had to be maintained despite variations in the load, with winding engines the speed changed throughout the wind and the governor performed a different function.

For many years, winding engineman regulated the amount of steam taken by the engines by hand, giving maximum steam during the initial acceleration stage and then throttling back during the middle of the wind before shutting it off during deceleration.

This was satisfactory when shafts were shallow and winding speeds were low but as both depths and speeds increased, some means of automating the steam regulation became necessary and by the 1870s various mechanisms designed to reduce the steam once the winder was up to speed had been proposed. What they all required, however, was some means of automatically bringing them into operation once a certain speed had been reached.

Luckily, by then engineers had a better theoretical understanding of the way governors worked and it was realised that, by either changing the geometry of the mechanism of gravity-loaded pendulum governors or by changing the strength and pre-loading of spring-loaded centrifugal ones, the operation could be delayed until a certain speed had been reached, after which point the governor would quickly activate.

Sources:

- W J M Rankine 1878, A manual of the steam engine and other prime movers

- A Jamieson 1906, A text-book on steam and steam engines

- D K Clark 1894, The steam engine

Copyright © 2005 - 2020 J.S. Thatcher

Page updated on:

02 Aug, 2020

at

02:34:32 PM

In case of problems contact: