Section under development

The Lilleshall bed-frame is a traditional box type, all sections of which were originally made of cast-iron. It has been altered considerably over the years and two major repairs have left only about 1/3 of the original in-situ.

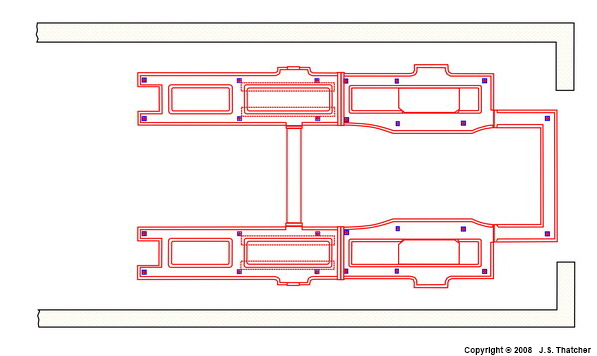

North winder Lilleshall original bed-frame and bed-bolt layout 1904

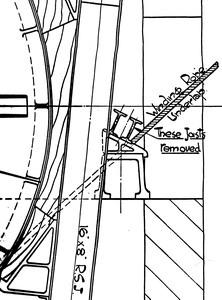

The first major change occurred with the removal of the cross-member on the front section which would have formed an essential part of the bracing. When this occurred is unknown - perhaps it was never fitted in that form to start with. The winder was fitted with a band brake and some means of supporting the front tension bolts would have been required. There is no obvious facility for this in the 1904 drawings, however, so a different front section, which could provide this may have been fitted.

When the full band brake was installed in 1924, the cross-member consisted of two girders mounted on inclined brackets secured by the end bed-bolt of the side members. The cross-girders carried the tensioning rods for each brake band.

The final change occurred when the Blacks Spring brake was fitted in 1931 and involved the complete removal of the front cross-girders fitted in 1924.

North winder 1924 brake-strap front cross-girders

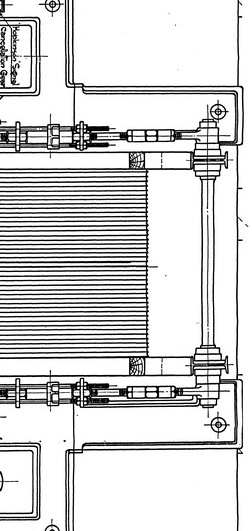

North winder front bed-frame arrangement - post 1931

The 1924 changes appear to have compromised the integrity because in June 1930 a small crack appeared in the LH bearing housing of the drum shaft. The bed was plated, but in January 1931 another crack appeared in the bearing housing. This was also plated until a replacement mid-section could be obtained.

Unfortunately, Lilleshalls had recently closed their foundry and the replacement casting had to be sought elsewhere. This was ordered in April 1931 from Thornwill and Warham and was delivered in mid November. Luckily, it arrived just in time because on Thursday, December 9th, the LH bed cracked right through the drum bearing pedestal. Mr Bryant, the head engineer and Mr Meins, the manager carried out the repair and, amazingly, within three days had the new bed installed and the pit resumed winding on Monday December 14th.

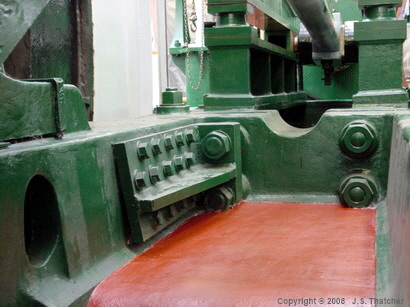

North winder LH front bed section - post 1931. The stencilled marking reads: “MAKERS - THORNWILL & WARHAM - ENGINEERS - BURTON ON TRENT” The rusted area is where the crack which occurred in 1969 was stitched.

The underlying structural weakness appears to have remained however, because the RH bed-frame was later to fracture. This time all three sections of the bed were replaced by Markhams. Instead of casting replacements, however, the new sections were entirely fabricated from steel plate. Exactly how long it took to install the new bed is not known, but it would have been considerably longer than the 1931 repair since the entire RH engine including the cylinder, piston, cross-head slides, con-rod, reversing linkage etc. had first to be dismantled and then refitted and trued-up.

North winder original Lilleshall LH rear bed-frame

North winder fabricated Markham RH bed-frame

A few years later the problem resurfaced again. At the end of the night shift of the morning of the 21st April 1969 a fracture was seen in the inner member of the LH middle section adjacent to the crank pit and winding had to be halted. The NCB Area Mechanical Engineer was informed and made an inspection but could find no obvious cause. There was no sign of a defect in the foundations underneath the bed-frame, the engine had been examined the previous day and the engine-man had not seen or heard anything unusual.

He concluded that the engine could continue coal winding provided additional supports were placed at either end of the bed and that the acceleration of the engine was limited. Man riding could not be allowed, however, until a repair had been effected.

It was decided to perform an initial repair by metal stitching and an engineer from Metalock was called immediately to the pit. It was estimated that this would take about 36 hours and work lasting 8 hours began at 9pm that evening. Subsequent work lasting 5 - 6 hours each time took place on the following night shifts.

Once this initial repair had been completed, Markhams fabricated a reinforcing bracket which was then bolted over the fracture area and normal operations were resumed. A section of the cast iron bed was removed for analysis but there is no record of the results and no subsequent modifications appear to have been made.

North winder LH bed 1969 reinforcement bracket

References

- Lilleshall drawings for the North Pit winder

- Stanton Ironworks Co. archives.

- Stanton and Stavely, A Business History. S D Chapman

- NCB North Derbyshire Area records

- Markham engineering drawing #

Copyright © 2005 - 2020 J S. Thatcher

Page updated on:

27 Jul, 2020

at

08:54:40 PM

In case of problems contact: